President & CEO

Matsuoka Satoshi

With our superior technology and quality, Pacific Steel mfg. is friendly to nature and contributes to society.

Pacific Steel Mfg. was established in 1938 to manufacture steel forgings and special alloyed iron. Today, we have an 8,000-ton press, and we have developed in Toyama as one of the few manufacturers in Japan that specializes in forged steel products.

We manufacture steel forgings industrially by hot free forging using a large press machine, as just like a blacksmith burns iron and strikes it with a hammer to make iron products by hand. A large steel product can weigh up to 50 tons.

Our main products are "NT rolls", which are cast iron forged rolls developed using our own technology for rolling various shaped steel such as rails, H-shapes, and steel sheet piles. Parts for various generators, such as turbine rotors, generator shafts, and turbine valves, which are incorporated in various power plants. We also have forgings for ships and various industrial plants.

These products are manufactured using our unique technology and have earned the high trust of many users. I don't think the general public usually sees it, but I am proud that it will greatly contribute to social infrastructure.

Amid calls for the Sustainable Development Goals, all of our employees are proud to work on "manufacturing" under the corporate philosophy of "contributing to society in an environmentally friendly way through superior technology and quality". We intend to grow as a company that can contribute to reducing the burden on the environment.

President & CEO

Matsuoka Satoshi

Pacific Steel Mfg. recognizes the environmental impact of the business activity of manufacturing forged steel products, and has set the following basic policy to reduce the environmental burden and will work diligently.

1. Harmony

We aim to be a factory that is in harmony with the environment by preventing pollution while continuously improving by practicing the PDCA cycle.

2. Recycling

We will work to reduce electricity and fossil fuels and reuse industrial waste such as slag and dust to promote the formation of a recycling-oriented society.

3. Law‐abiding

Be aware of social responsibility as a sensible corporate citizen and comply with environment-related laws and regulations.

Iron is a material that can be recycled many times, and almost all of it is collected and reused. At Pacific steel mfg., the iron scraps generated by machining are melted again in an electric furnace and used for manufacturing. The power plant materials we make are also used in power plants that use renewable energy such as geothermal power generation and biomass power generation. We are doing eco-friendly business using iron.

Ltd. recognizes that the safety and health of our employees and subcontractors takes precedence over everything else, and we will work to ensure a safe and comfortable work environment.

1.We respect consultation and participation with workers, recognizing that safety and health are achieved through good communication.

2.We will comply with safety and health-related laws and regulations, as well as our own safety and health rules and regulations, and establish necessary voluntary standards in pursuit of zero accidents and zero occupational injury.

3.Conduct risk assessments at all workplaces to prevent occupational accidents.

4.Utilize the results of stress checks to improve the work environment.

5.In order to promote a "comfortable workplace" and "mental and physical health," we will strive to create a rewarding work environment by preparing its environmental facilities.

6.In implementing this policy, we will allocate appropriate management resources and strive to continuously improve its operation.

| Company Name | Pacific steel Mfg.Co.,Ltd. |

|---|---|

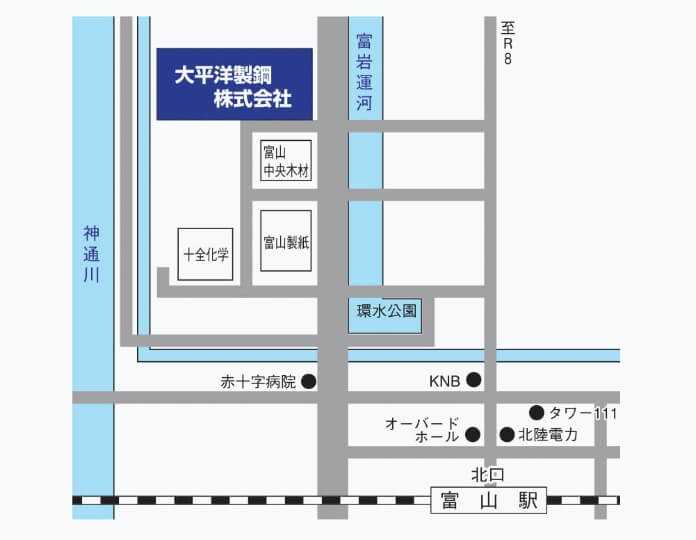

| Locations | [Headquarters/Factory] 1-93 Shimoshin-Nissomachi, Toyama City, Toyama Japan Google Map [Tokyo Office] Marunouchi Eiraku Building 1-4-1, Marunouchi, Chiyoda-ku, Tokyo Japan Google Map |

| Representative | President and CEO satoshi matsuoka |

| Contact | [Headquarters/Factory] TEL +81-76-432-4175 [Tokyo Office] TEL +81-3-4243-1260 |

| Foundation | April 1938 |

| Capital | 700 million yen |

| Number of Employees | 215(198 male and 17 female; as of April 1, 2024) |

| Main Products | Power generation-related components, mill rolls for section steel hot rolling (NT Rolls), suction rolls for paper making, calender rolls, marine engine components, and other steel forgings for all kinds of industrial machinery components |

| Main Customers and Suppliers | Nippon Steel Corporation / Mitsubishi Heavy Industries, Ltd. / JFE Steel Corporation. / Toshiba Energy Systems & Solutions Corporation / Primetals Technologies Japan / Ebara Elliott / Dongkuk Steel Mill Co., Ltd. / / Nucor-Yamato Steel Company / Elliott Group / |

| Employee Facilities | [Company dormitory] 3-story building, 20 rooms |

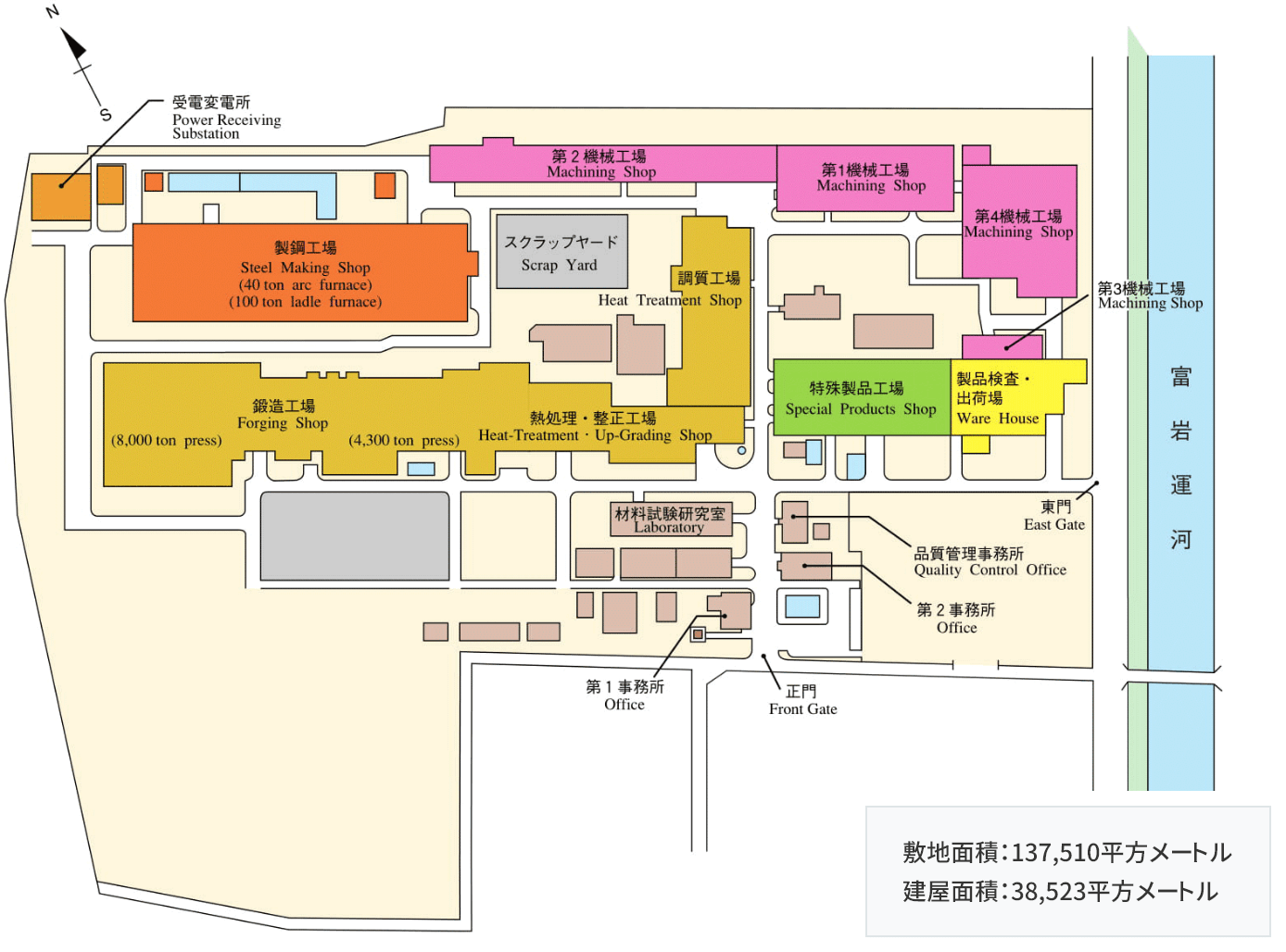

Layout of Factory

| Apr. 1938 | The Company is established by Nippon Soda Co., Ltd. for the purpose of manufacturing steel forgings and special alloy iron. |

|---|---|

| Dec. 1949 | In accordance with the Enterprise Reorganization Act, the Company splits from Nippon Soda Co., Ltd. and changes its name to Nisso Steel MFG. Toyama Factory. |

| Apr. 1963 | The Company develops NT Rolls putting high-carbon cast iron material through a special treatment. |

| Mar. 1966 | Production of iron sand pig and other materials is discontinued, and the Company becomes a factory specialized in steel forgings. |

| May 1966 | The Company is granted rights for the regular manufacture and sale of NT Rolls by Yawata Iron & Steel Co., Ltd. (now Nippon Steel Corporation). |

| Jun. 1969 | The Company obtains a Japanese patent for NT Rolls. |

| Jan. 1970 | The Company merges with Pacific Nickel Corporation and changes its name to Pacific Metals Co., Ltd. Toyama Factory. |

| Aug. 1971 | New 3,600-ton forging press shop is opened. |

| May 1974 | New 40-ton Electric Arc furnace is installed. |

| Jan. 1982 | New 20-ton ESR furnace is installed. |

| Jul. 1984 | The Company splits from Pacific Metals Co., Ltd. and changes its name to Pacific Steel MFG. Toyama Works. |

| Sep. 1990 | Capacity of 3,600-ton press is increased to 4,300 tons. |

| Apr. 1994 | New 40-ton ladle refining furnace is installed. |

| Nov. 1999 | ISO-9002 certification is obtained for carbon steel, alloy steel and stainless steel forgings. |

| Nov. 2003 | Updated to ISO 9001 certification. |

| Jun. 2008 | New 50-ton VOD equipment is installed. |

| Jul. 2010 | Fourth machining shop is opened. |

| Jan. 2011 | New 8,000-ton forging press shop is opened. |

| Oct. 2011 | The Company obtains ISO14001 certification. |

| Jan. 2017 | 100-ton ladle furnace began operartion. |

Pacific Steel Mfg.Co.,Ltd.

1-93, Shimoshin-Nissomachi, Toyama Japan 930-0808

Mon-Fri 8:30 am - 4:50 pm(JST)

(Excluding Saturdays, Sundays, public holidays, summer holidays and New Year's holidays)